Expert Guide to Choosing the Perfect Lapidary Blade

Precision stone cutting demands exceptional tools, and selecting the right lapidary blade can transform an ordinary project into a masterpiece. Whether you're crafting intricate jewelry, shaping decorative stones, or working on industrial applications, understanding the nuances of blade selection directly impacts your results. Professional lapidary artists know that their cutting tool represents the difference between clean, precise cuts and frustrating material waste.

The evolution of stone cutting technology has brought us sophisticated cutting solutions that our predecessors could hardly imagine. Modern lapidary work combines centuries-old techniques with cutting-edge materials science, creating opportunities for both amateur enthusiasts and seasoned professionals to achieve remarkable results. Today's blades incorporate advanced diamond technology, engineered bonding systems, and precision manufacturing that deliver consistent performance across diverse stone types.

Understanding how different blade characteristics affect cutting performance becomes essential for anyone serious about lapidary work. The relationship between blade construction, stone properties, and cutting technique creates a complex equation that determines project success. Mastering these relationships elevates your work from basic cutting to true artistry.

Understanding Blade Construction Fundamentals

Modern lapidary blades represent sophisticated engineering achievements that balance multiple performance factors. The core structure typically consists of a steel substrate that provides mechanical strength while maintaining flexibility under operating stresses. This foundation supports the cutting medium, usually industrial diamonds or other abrasive materials, which performs the actual material removal.

The bonding matrix surrounding these abrasive particles plays a crucial role in blade performance characteristics. Metal bonds offer exceptional durability and work effectively with harder materials, while resin bonds provide smoother cutting action on softer stones. Some specialized applications require electroplated surfaces where diamonds adhere directly to the blade body through electrochemical processes.

Blade geometry significantly influences cutting behavior and application suitability. Rim thickness affects kerf width and cutting precision, while diameter determines maximum cutting depth. The relationship between these dimensions creates specific performance characteristics that suit different project requirements.

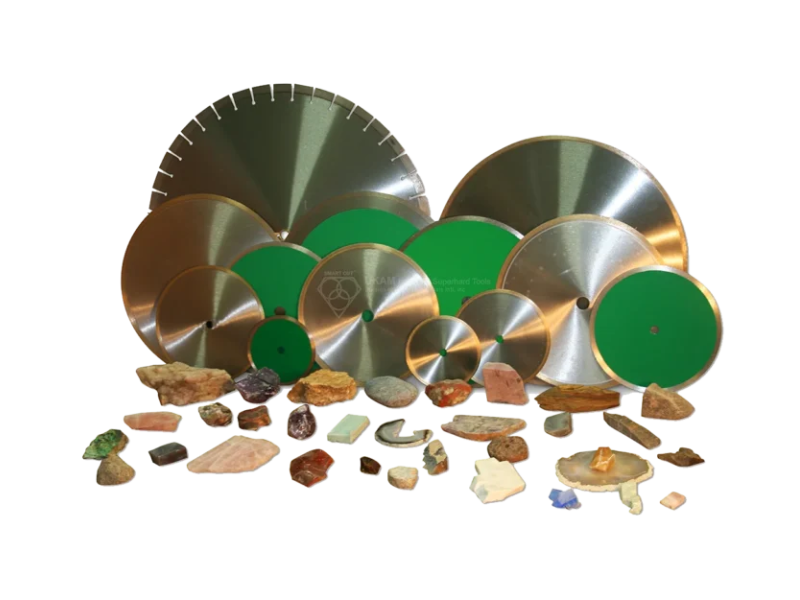

Blade Types and Their Specific Applications

Sintered Diamond Technology

Sintered diamond blades represent the pinnacle of cutting technology for demanding applications. The manufacturing process involves mixing diamond particles with metal powders under extreme heat and pressure, creating a homogeneous cutting matrix throughout the blade segment. This construction ensures consistent cutting performance as the blade wears, maintaining efficiency throughout its operational life.

These premium blades excel when working with challenging materials like agate, jasper, and crystalline quartz. Their aggressive cutting action and extended lifespan justify higher initial costs through reduced replacement frequency and superior productivity. Professional workshops often standardize on sintered diamond blades for production environments where consistency and reliability matter most.

Electroplated Diamond Solutions

Electroplated diamond blades offer distinct advantages for specific applications requiring smooth surface finishes. The manufacturing process deposits a single layer of diamond particles onto the blade surface through electrochemical methods, creating an initially very aggressive cutting surface that produces exceptionally smooth cuts.

While these blades lose cutting efficiency as surface diamonds wear away, they provide unmatched surface quality during their initial cutting life. This characteristic makes them particularly valuable for finishing operations where surface texture directly affects final product quality.

Continuous vs. Segmented Rim Design

Rim configuration dramatically affects cutting characteristics and cooling efficiency. Continuous rim blades provide the smoothest possible cuts with minimal material chipping, making them ideal for applications where surface finish matters most. However, their solid construction limits heat dissipation and debris removal, potentially reducing cutting speed and blade life.

Segmented blades incorporate gaps in the cutting rim that enhance cooling and allow debris evacuation during cutting operations. These design features enable faster cutting speeds and improved blade longevity when working with abrasive materials, though they may produce slightly rougher cut surfaces requiring additional finishing work.

Material-Specific Cutting Strategies

Different stone types require tailored approaches that consider hardness, brittleness, and structural characteristics. Understanding these material properties enables optimal blade selection and cutting parameter optimization for superior results.

Soft Stone Cutting Techniques

Soft materials like soapstone, alabaster, and certain types of marble require careful blade selection to prevent material tearing or excessive removal rates. Fine-grit blades with resin bonding systems work exceptionally well for these applications, providing controlled cutting action that preserves material integrity.

Cutting parameter optimization becomes critical when working with soft stones. Excessive cutting speeds can cause blade loading where debris accumulates in the cutting matrix, reducing efficiency and potentially damaging both the blade and the workpiece. Maintaining moderate speeds with adequate cooling prevents these issues while ensuring smooth, predictable cutting action.

Hard Gemstone Processing

Hard materials, including sapphire, ruby, and various quartz varieties, demand aggressive cutting action from coarse-grit, metal-bonded blade systems. These combinations provide necessary cutting power while maintaining structural integrity under high-stress conditions that would destroy lighter blade constructions.

Cooling becomes absolutely critical when processing hard gemstones to prevent thermal damage to both the cutting tool and the workpiece. Inadequate cooling can cause blade glazing, where the cutting surface becomes smooth and ineffective, or worse, thermal shock that creates internal fractures in valuable gemstone material.

Managing Brittle Material Challenges

Brittle stones such as obsidian, certain jaspers, and glass-like materials present unique challenges requiring specialized cutting approaches. These materials tend to fracture unpredictably, making conventional cutting techniques potentially destructive.

Thin, fine-grit blades with continuous rim construction typically produce optimal results with brittle materials. Combined with reduced cutting speeds and minimal feed pressure, this approach minimizes stress concentrations that could trigger catastrophic fracturing. Patient, methodical cutting techniques preserve material integrity while achieving desired geometric results.

Essential Diamond Lapidary Tools for Professional Results

Successful lapidary work extends far beyond blade selection to encompass a complete system of complementary tools and equipment. Professional-grade lapidary saws provide the stable, vibration-free platform necessary for precision cutting operations. These machines typically feature robust construction, accurate adjustment mechanisms, and integrated cooling systems.

Proper blade mounting hardware ensures safe, efficient operation while maximizing blade performance. Quality flanges distribute clamping forces evenly across the blade body, preventing warping or premature failure. Arbor systems must match blade specifications precisely to maintain concentricity and prevent dangerous vibrations.

Cutting guides, jigs, and fixtures transform basic cutting operations into precision manufacturing processes. These accessories enable repeatable cuts, complex angles, and intricate geometries that would be impossible through freehand techniques alone. Investment in quality workholding solutions pays dividends through improved accuracy and reduced material waste.

Maintenance Protocols for Optimal Performance

Systematic maintenance extends blade life significantly while ensuring consistent cutting performance throughout the blade's service period. Regular cleaning removes accumulated debris that can impair cutting efficiency and accelerate wear patterns.

Cleaning and Storage Procedures

Post-use cleaning involves thorough debris removal using appropriate solvents and cleaning tools. Avoid harsh chemicals that might damage bonding matrices or blade substrates. Soft brushes effectively remove stubborn particles without damaging delicate cutting surfaces.

Proper storage prevents corrosion and physical damage between uses. Vertical storage racks maintain blade geometry while providing easy access for selection. Climate-controlled storage areas prevent condensation that could cause corrosion on metal components.

Performance Monitoring

Regular inspection identifies wear patterns and developing problems before they compromise cutting quality. Visual examination should focus on cutting surface condition, overall blade geometry, and mounting area integrity. Documentation of blade performance helps establish replacement intervals and identify optimal operating parameters.

Cutting performance degradation often occurs gradually, making systematic monitoring essential for maintaining productivity. Tracking cutting speeds, surface quality, and material removal rates provides objective data for replacement decisions.

Safety Excellence in Lapidary Operations

Lapidary work involves high-speed rotating equipment that presents significant safety risks requiring comprehensive safety protocols. Personal protective equipment represents the first line of defense against injury from flying debris, dust exposure, and accidental contact with cutting surfaces.

Eye protection must meet industrial impact standards to protect against high-velocity stone particles. Side shields and wrap-around designs provide comprehensive coverage during cutting operations. Regular inspection and replacement of damaged safety glasses maintains protection effectiveness.

Respiratory protection becomes critical when cutting materials that generate harmful dust particles. Many stones contain silica or other hazardous minerals that pose serious health risks with prolonged exposure. Proper ventilation systems or respiratory protection equipment prevent dangerous accumulations in work areas.

Advanced Cutting Methodologies

Professional lapidary work often requires sophisticated cutting techniques that maximize material utilization while achieving complex geometries. These methods demand a thorough understanding of both material behavior and cutting tool capabilities.

Precision Curve Generation

Creating smooth curves requires careful coordination between blade selection, cutting speed, and feed rate. Thin, flexible blades work better for tight radius cuts, while maintaining steady advancement prevents blade binding and breakage. Practice on inexpensive materials develops the muscle memory and technique necessary for working with valuable stones.

Complex Angle Cutting

Accurate angular cuts demand precise setup and measurement techniques. Digital angle measurement tools and custom fixtures ensure repeatable results for complex geometries. Investment in quality measurement equipment prevents costly errors on expensive materials.

Production Cutting Strategies

High-volume production requires optimization of cutting parameters for maximum efficiency while maintaining quality standards. Systematic experimentation identifies optimal combinations of blade type, cutting speed, and cooling for specific material combinations.

Economic Analysis of Blade Selection

Lapidary blade economics extend beyond simple purchase price considerations to include performance characteristics, longevity, and project-specific requirements. Total cost of ownership calculations provide more accurate comparisons between different blade options.

Premium blades often deliver superior value through extended cutting life, reduced replacement frequency, and improved cut quality that reduces finishing requirements. These factors frequently offset higher initial costs through improved productivity and reduced material waste.

Project-specific considerations include material value, required precision, and production volume. Expensive gemstones justify premium blade investment to minimize waste and maximize yield, while practice materials might use more economical options.

Troubleshooting Common Cutting Issues

Systematic problem-solving approaches help identify and resolve cutting issues quickly, minimizing project delays and material waste. Understanding cause-and-effect relationships between symptoms and root causes enables effective solutions.

Addressing Blade Loading

Blade loading occurs when debris accumulates in the cutting matrix, drastically reducing cutting efficiency. This typically results from inappropriate cutting parameters or inadequate cooling systems. Immediate cleaning and parameter adjustment usually resolve the issue.

Eliminating Surface Defects

Chipping, fracturing, and rough surface finishes often indicate inappropriate blade selection or cutting parameters. Systematic evaluation of blade type, grit size, and cutting speed typically identifies solutions.

Extending Blade Life

Premature blade wear suggests operating parameter problems or compatibility issues between the blade and mthe aterial. Careful analysis of cutting conditions helps identify optimization opportunities.

Future Developments in Cutting Technology

Advancing materials science continues to improve blade performance and expand application possibilities. New diamond synthesis techniques and bonding technologies promise enhanced cutting efficiency and extended blade life.

Integration of computer-controlled cutting systems brings precision manufacturing capabilities to smaller workshops. These developments make complex cuts more accessible while improving repeatability and reducing skill requirements.

Environmental considerations drive the development of sustainable cutting fluids and recyclable blade materials. These innovations maintain performance while reducing the environmental impact of lapidary operations.

Frequently Asked Questions

How do I know when to replace my lapidary blade?

Replace blades when cutting efficiency drops noticeably or when visible wear affects cut quality, typically after 15-40 hours, depending on materials and usage.

What cooling fluid works best for diamond blades?

Clean water works excellently for most applications, though some specialized blades may require specific cooling solutions per manufacturer recommendations.

Why does my blade vibrate excessively during cutting?

Excessive vibration usually indicates improper mounting, worn arbor components, or blade damage requiring immediate inspection and correction.

How should I store blades to prevent warping?

Store blades vertically in proper racks away from temperature extremes and moisture to maintain flatness and prevent corrosion.

What causes sudden drops in cutting speed?

Sudden speed reduction typically indicates blade loading, damage, or cooling system problems requiring immediate attention and correction.

Can I use the same blade for all stone types?

While some blades work across multiple materials, optimal results require matching blade characteristics to specific stone properties and project requirements.

Mastering lapidary blade selection and usage opens doors to unlimited creative possibilities in stone cutting and shaping. Through understanding these fundamental principles, craftspeople can achieve professional results while working safely and efficiently across diverse project requirements.

- Seo

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Business & Money