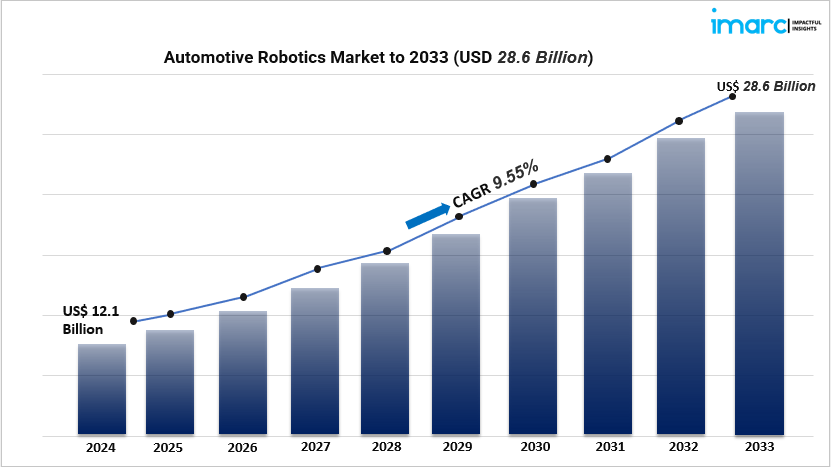

Explosive Growth Forecast: Automotive Robotics Market to Double by 2033

Market Overview

The automotive robotics market sector is accelerating, with its global market value estimated at USD 12.1 billion in 2024, projected to nearly double to USD 28.6 billion by 2033—a robust CAGR of 9.55%. This remarkable growth is fueled by rising adoption of automation across automotive manufacturing, the electrification wave, integration of AI and Industry 4.0, and consumer-driven demand for customization.

Study Assumption Years

- BASE YEAR: 2024

- HISTORICAL YEAR: 2019–2024

- FORECAST YEAR: 2025–2033

Automotive Robotics Market Key Takeaways

- Market is valued at USD 12.1 billion (2024), forecast to reach USD 28.6 billion by 2033 at a 9.55 % CAGR.

- Asia-Pacific dominates, led by China, Japan, Korea, and India, driven by booming automotive manufacturing and automation initiatives.

- Among robot types, articulated robots hold the largest share due to flexibility in complex tasks.

- Component-wise, robotic arms lead, essential for welding, painting, and assembly.

- By application, welding ranks top, thanks to precision, speed, and consistency in auto assembly.

- End-user base: vehicle manufacturers are primary adopters, though component producers also rely heavily on robotics.

- Strong tech integration trends: AI, IoT, cobots, and EV-oriented automation continuing to fuel advancements.

Market Growth Factors

1. Technological Advancements & Industry 4.0 Integration

Technological innovation is really driving the automotive robotics market forward. With the integration of AI, IoT, advanced sensors, and analytics, we're seeing a new level of precision and autonomy in robotic systems. Robotic welders, painters, and quality-control units are becoming more self-optimizing and adaptable than ever. The emergence of collaborative robots—or cobots—that can work alongside human employees without the need for heavy guarding is enhancing flexibility, cutting down on floor space, and making deployment a breeze. On the electric vehicle (EV) production front, the demand for highly specialized and precise processes—from battery pack assembly to body welding—is pushing the adoption of smart, customizable robot systems. These systems are part of the Industry 4.0 ecosystem, which supports remote monitoring, predictive maintenance, and real-time optimization, leading to greater efficiency, less downtime, and improved quality assurance—all of which further fuel market growth.

2. Regulatory Environment & Safety Standards

At the same time, global regulatory pressures surrounding worker safety, environmental compliance, and energy efficiency are transforming automotive manufacturing. Governments and industry organizations are setting higher standards for accident prevention, emissions, and working conditions. Robotics play a crucial role in meeting these standards: enclosed welding robots significantly reduce human exposure to harmful fumes; automated painting processes eliminate inhalation risks for workers; and heavy-lifting robots help protect laborers from repetitive strain injuries. Additionally, environmental regulations are pushing for efficiency gains—shorter cycle times and waste reduction through precision robotics are key to achieving sustainability goals. In regions like Asia-Pacific, subsidies, grants, and policy incentives are promoting industrial automation technologies in manufacturing. As these regulations become stricter, they encourage automotive OEMs and suppliers to modernize their production lines, which in turn boosts the demand for robotics and enhances long-term integration prospects.

3. Automotive Industry Dynamics & Customized Demand

The rapid rise in vehicle production—especially electric vehicles (EVs)—along with a growing consumer desire for personalization, is transforming factory floors. Production levels are climbing in emerging markets like India, China, and Southeast Asia, which calls for scalable and flexible automation solutions. Robotics play a crucial role in supporting modular manufacturing for various vehicle models and trim levels without the need for extensive retooling. When it comes to EVs, tasks like battery module assembly, precise fitting of electric drivetrains, and adhering to high-voltage safety protocols all require automation. Plus, the increasing demand from customers for specialized features—like custom interiors, colors, and finishes—means that adaptable robotic systems are a must. Manufacturers are turning to robotics to reliably manage a range of tasks, ensure consistent quality, and shorten lead times. This fast-paced production landscape is speeding up the integration of robotics and justifying long-term investments in automation infrastructure.

Request for a sample copy of this report: https://www.imarcgroup.com/automotive-robotics-market/requestsample

Market Segmentation

Breakup by Product Type:

- Cartesian Robots – Linear axis robots for high‑speed pick‑and‑place and material handling.

- SCARA Robots – Flexible four‑axis systems for assembly and dispensing tasks.

- Articulated Robot – Multi‑joint robots offering max flexibility for welding, assembly, etc.

- Others – Including cylindrical, delta, cart-pole and other niche forms.

Breakup by Component Type:

- Controller – The robot brain managing motion and coordination.

- Robotic Arm – The primary motion unit performing tasks.

- End Effector – Tools at the arm’s end (grippers, welding torches, etc.).

- Drive and Sensors – Motors and sensing systems for motion and control.

Breakup by Application:

- Assembly – Fitting vehicle components like engines and seats.

- Dispensing – Applying adhesives, sealants, and paint accurately.

- Material Handling – Loading/unloading parts, conveyors, packaging.

- Welding – Precision joining of automotive components.

- Others – Inspection, painting, cleaning, etc.

Breakup by End User:

- Vehicle Manufacturers

- Automotive Component Manufacturers

Breakup by Region:

• North America (United States, Canada)

• Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

• Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

• Latin America (Brazil, Mexico, Others)

• Middle East and Africa

Regional Insights

The Asia-Pacific region continues to be a powerhouse, with a strong uptake of robotics in countries like China, Japan, Korea, and India. This surge is fueled by the rapid expansion of automotive production, government incentives for automation, and local robotics manufacturing hubs, creating a balance between cost efficiency and advanced technology integration. The region's dominance is reinforced by the growing number of EV lines, AI-driven factories, and scale advantages—solidifying its leadership and appeal among global original equipment manufacturers (OEMs).

Recent Developments & News

Robotic manufacturers are really pushing the envelope these days! AI-enabled vision systems have become quite common, allowing for quick adjustments in workspaces and thorough quality checks. Cobots have made significant strides too, now featuring better safety measures and compact designs that are perfect for flexible automation. We're also seeing the rise of robotic lines specifically for electric vehicles, concentrating on battery and drivetrain assembly. Plus, the trend of consolidating through partnerships and mergers is boosting research and development, speeding up the rollout of next-generation robotics among OEMs and Tier-1 suppliers.

Key Players

- ABB Ltd.

- Denso Wave Incorporated (DENSO Corporation)

- Dürr Aktiengesellschaft

- FANUC

- Harmonic Drive Systems Inc.

- Kawasaki Heavy Industries Ltd.

- KUKA Aktiengesellschaft (Midea Group)

- Nachi‑Fujikoshi Corp.

- Omron Corporation

- Seiko Epson Corporation

- Yamaha Motor Co. Ltd.

- Yaskawa Electric Corporation

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=5185&flag=C

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services. IMARC offerings include a thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No: +1-631-791-1145

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Script

- App