High Altitude Platform System & Composite Manufacturing: Building Superior Aerial Structures

Introduction: The Sky Is No Longer the Limit

In the modern aerospace world, innovation has taken to the stratosphere—literally. The demand for long-duration aerial platforms has led to the rise of the high altitude platform system (HAPS). These advanced systems, floating or flying at altitudes between 20 to 50 kilometers above the Earth's surface, serve vital roles in telecommunications, defense, surveillance, and environmental monitoring.

But such systems wouldn’t be possible without the breakthroughs in composite manufacturing. As the backbone of next-generation aerospace design, composites make these high-altitude platforms lighter, stronger, and more efficient. The partnership between high altitude systems and composite engineering is shaping a new frontier in aerial technology.

What Is a High Altitude Platform System?

A high altitude platform system is an airborne structure that operates in the stratosphere, well above commercial air traffic but below satellites. These platforms can be balloons, airships, or aircraft powered by solar energy or other long-endurance technologies.

Core purposes of HAPS include:

-

Providing temporary or backup communication networks

-

Supporting disaster recovery through aerial surveillance

-

Enabling military reconnaissance in remote areas

-

Collecting environmental data such as atmospheric gases or weather patterns

Because they operate above weather systems and offer broader line-of-sight, HAPS can act like low-orbit satellites with lower costs and faster deployment.

Why Composite Manufacturing Is Critical

Reaching and remaining in the stratosphere for extended periods requires platforms that are exceptionally light, durable, and efficient. This is where composite manufacturing plays an essential role.

Composites are materials made by combining two or more substances with different physical or chemical properties. In aerospace, carbon fiber-reinforced polymers are commonly used due to their superior strength-to-weight ratio.

Benefits of composite materials for HAPS:

-

Lightweight Structure: Reduces the energy required for lift and propulsion

-

High Strength: Withstands wind shear, UV exposure, and temperature swings

-

Fatigue Resistance: Maintains structural integrity over long durations

-

Customization: Easily formed into complex aerodynamic shapes

Without composites, building a long-endurance platform that operates at high altitudes would be practically impossible.

The Intersection of HAPS and Composites: A Perfect Match

Designing a high altitude platform system demands the perfect balance of strength and weight. Traditional aerospace materials like aluminum may be strong, but they are too heavy for HAPS to remain airborne for weeks or months. Composites fill this gap beautifully.

How composites support HAPS performance:

-

Wing Design: Composite wings are lightweight and flexible, allowing large spans without structural failure

-

Solar Integration: Flat and curved surfaces can be embedded with solar cells without compromising strength

-

Payload Housing: Sensitive sensors and communication gear are encased in custom composite pods

-

Frame Durability: Resists high UV levels and atmospheric stress at altitudes above 20 km

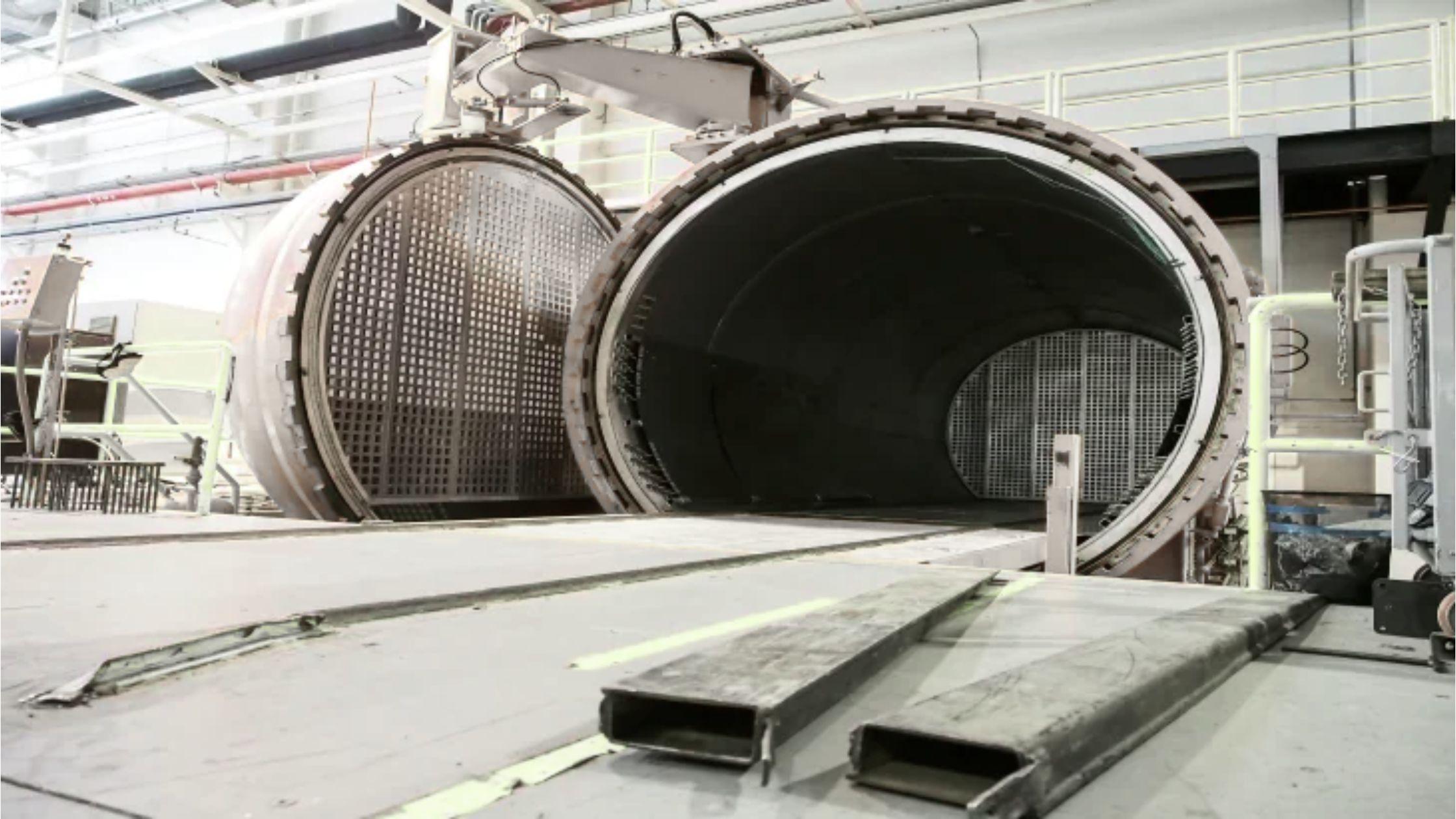

Swift Engineering, among others, uses advanced composite manufacturing processes like automated fiber placement and autoclave curing to build efficient and durable HAPS frames.

Real-World Applications of HAPS

The versatility of high altitude platforms is reflected in their growing adoption across multiple industries.

Popular use cases:

-

Telecommunications: Companies are testing stratospheric platforms as alternatives to ground towers in remote areas.

-

Military Surveillance: High-flying UAVs provide real-time visuals without needing satellite passes.

-

Agriculture and Mining: HAPS support precision mapping, crop health analysis, and remote area imaging.

-

Environmental Science: Climate researchers use HAPS to monitor ice melt, pollution levels, and atmospheric pressure.

All these applications depend on platforms that can endure long flights and extreme conditions—enabled only by reliable composite manufacturing.

Innovations in Composite Manufacturing for HAPS

The field of composite manufacturing is constantly evolving to meet the needs of aerospace developers. For high altitude platforms, this means lighter laminates, more sustainable resins, and smarter fabrication methods.

Key advancements include:

-

Nano-enhanced composites for added strength without added weight

-

Hybrid materials combining carbon fiber with lightweight foams

-

Out-of-autoclave curing techniques for faster and more efficient production

-

Digital design and simulation tools that optimize performance before a single layer is laid

These innovations allow engineers to create HAPS that are not only functional but also scalable and sustainable.

Challenges and Future Outlook

Although the technology is advancing rapidly, challenges remain in ensuring the commercial viability and durability of high altitude platforms.

Ongoing challenges:

-

Balancing cost with long-term reliability

-

Ensuring energy efficiency with solar-powered systems

-

Dealing with unpredictable atmospheric conditions

-

Maintaining regulatory compliance across countries and airspaces

Despite these obstacles, the future looks promising. With the ongoing improvements in composite manufacturing and autonomous system controls, the next decade could see HAPS become a mainstream tool for global connectivity and observation.

Conclusion: Strength Above the Clouds

The future of aerial innovation lies in the skies above commercial flight paths and below orbiting satellites. The combination of high altitude platform systems and composite manufacturing is not only advancing engineering standards—it is redefining what’s possible.

As these systems continue to develop, they promise new ways to connect, observe, and protect our planet. From emergency communication networks to long-term climate research, the fusion of strong, lightweight materials with intelligent airborne design will continue to build the future—above the clouds and beyond expectations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- Script

- App